Not only domestic greenhouse gas regulations, but also global regulations on our products such as IMO regulations are being enhanced.

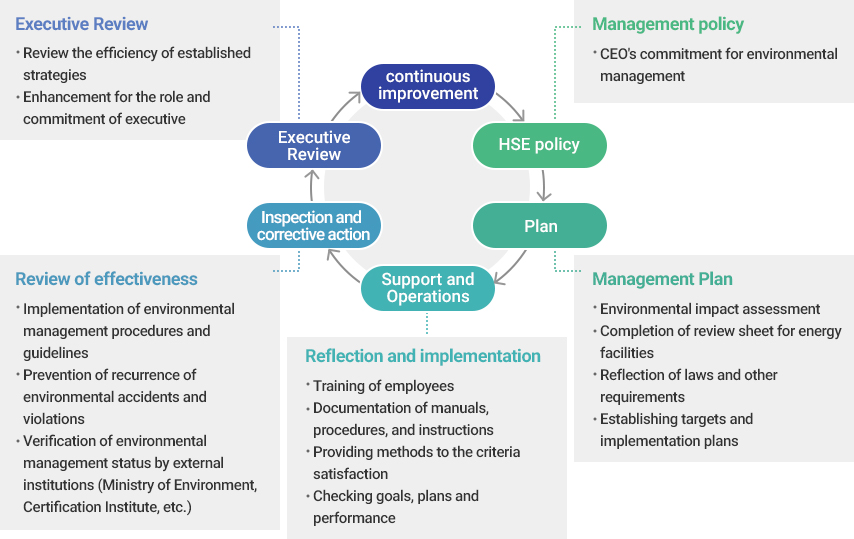

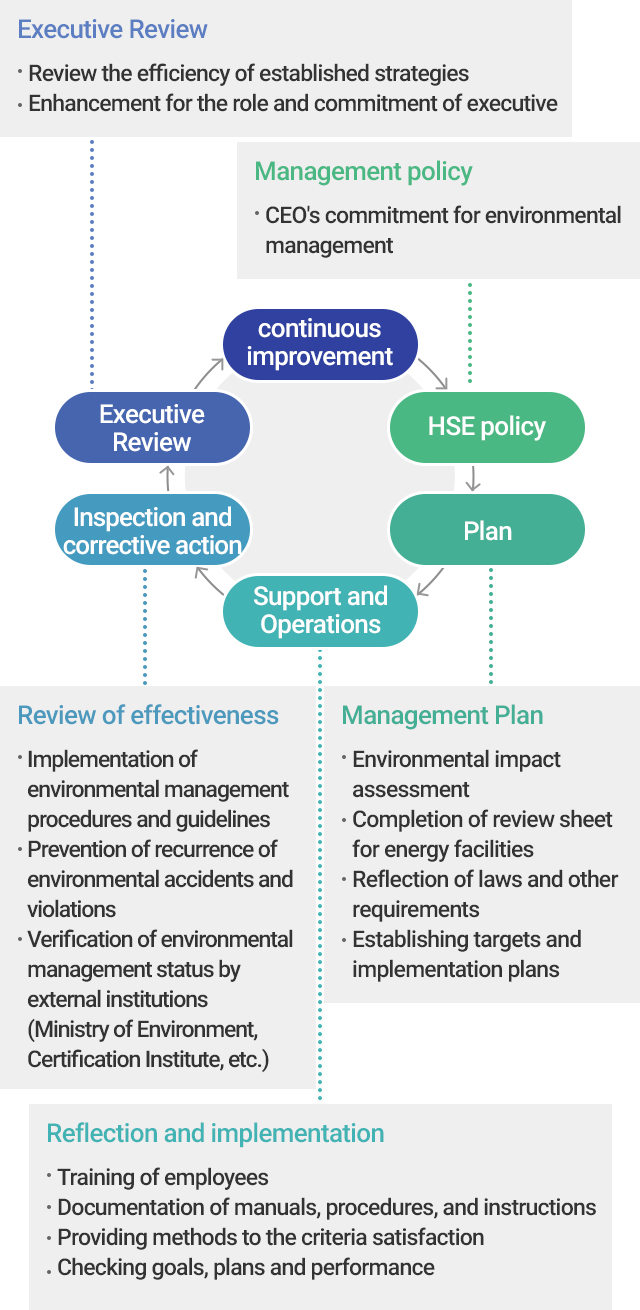

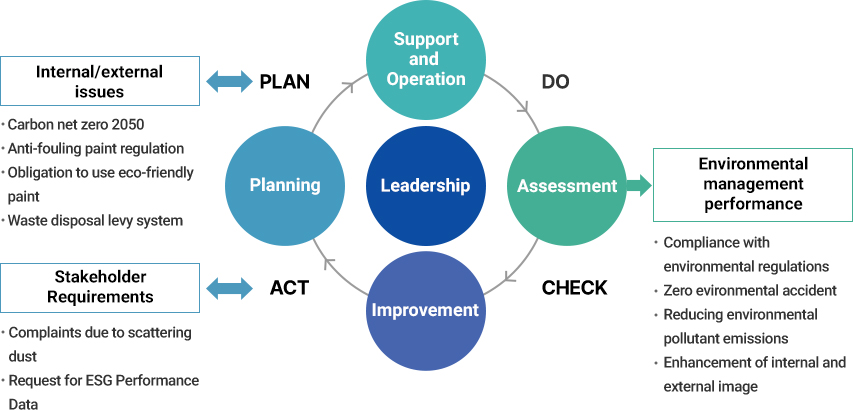

Samsung Heavy Industries is maintaining ISO14001 every year to establish an environmental management system and is striving in various ways to reduce environmental

risks such as environmental issue recognition, environmental performance monitoring, and environmental impact assessment. In addition, we established carbon net zero

roadmap decided on the ESG Committee in Oct. 2022 and are continuously enhancing by declaring environmental management through the CEO's New Year's message in Jan. 2023

Samsung Heavy Industries has implemented an HSE Management Policy guided by a people-centric philosophy to promote sustainable development and coexistence among people, society, and the environment.

This policy is rigorously applied across all corporation including sales and production, and both domestically and internationally, including subsidiaries and employees. It encourages compliance within the primary supply chain and promotes participation from customers, suppliers, and other stakeholders.

The company surpasses basic legal compliance by adopting an environmental management system aligned with global standards, focusing on climate change mitigation, resource efficiency, hazardous substance control, biodiversity protection, and anti-deforestation measures.

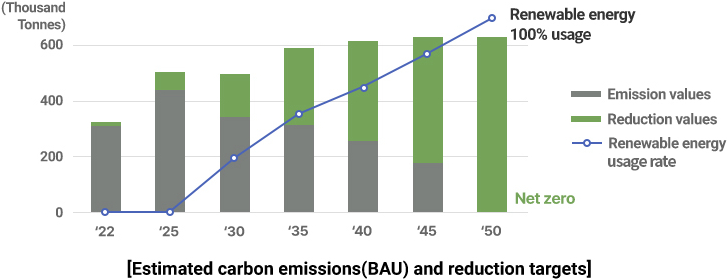

In order to respond quickly to changes in the business environment, where carbon is money, we established strategies and are implementing them. Samsung Heavy Industries will continuosly consider and improve to realize a carbon net zero shipyard, and will also strive to manage our suppliers.

Samsung Heavy Industries is establishing a company-wide GHG management system that manages GHG emissions based on IPCC international standards and domestic greenhouse gas emission calculation guidelines. We calculated GHG emissions not only from domestic but also from overseas sites, and are striving to comply with the annual GHG reduction target.

Closure of incineration

facilities

Fuel transition

Reduction of emissions

during sea trial

Due to the nature of shipbuilding industry, Samsung Heavy Industries' value chain GHG emissions (Scope 3) account for more than 99% of its total GHG emissions (Scopes 1, 2, and 3).

We developed a methodology and calculated emissions, which is the first step in managing Scope 3 GHG emissions. After that, it will be expanded to global standards by

supplementing the Scope 3 methodology specialized in the shipbuilding industry with three domestic shipbuilding companies and global Class. The use of our products will create a

new value for improving the global environment.

Scope 3

Scope 1, 2

Scope 3

Samsung Heavy Industries introduced an internal carbon pricing as a means of testing strategic and investment assumptions' vulnerability to stronger climate-related regulation and the broader emergence of carbon cost. When considering environmental investment, it gives financial value to future greenhouse gas emissions and uses them as investment decisions.

Create an investment proposal checklist

According to the 'Carbon cost calculation guide', it is checked whether carbon emissions and carbon costs is needed

Carbon cost calculation

Calculate carbon emissions and costs before and after the investment

Carbon Cost Review

check calculation logic consistency by ESG Strategy Group

Holding an investment council

Recognize carbon costs and use them as financial values

Samsung Heavy Industries is establishing an energy management system through ISO50001 certification and is striving to improve energy efficiency through a company-wide

monitoring system.

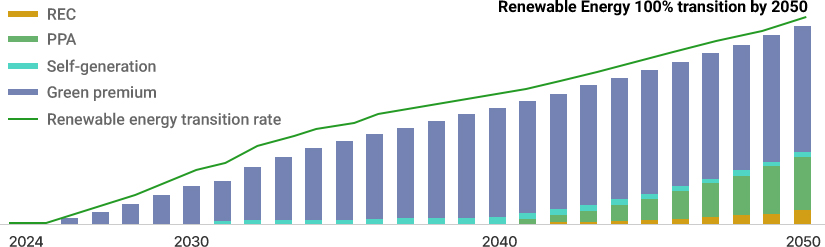

In addition, we established a specific implementation plan and conduct it to use renewable energy 100% by 2050.

Improve energy efficiency

Advanced energy management systems

Eliminate inefficiencies, monitor energy usage, etc

Introduce self-generation

Phased expansion of Solar energy

0.1MW in 2023~24 → 20MW in 2030 → 40MW in 2040(total)

Purchase renewable energy

Green Premium + PPA(after 2040)

Renewable energy will be purchased from 2025

Samsung Heavy Industries established a short, mid, and long-term roadmap for the development of low-carbon and de-carbon technologies and ships, and has received Approval in Principle from international authorized institutions.

Received Approval in Principle for design of 'CMSR Power Barge' from ABS Class

Developed 'Boil-off gas Recovery System(BRes)' for LNG Propulsion Ship (received Statement of Fact from ABS Class)

Received Approval in Principle for 'liquefied hydrogen fuel cell system' from DNV Class

Received Approval in Principle for design of 'ammonia-fueled large container ships' from ABS Class

Received Approval in Principle for 'Samsung Smart Power Limitation' for ship carbon emission control system from KR Class

Developed ship carbon capture technology 'OCCS' and Received Approval in Principle from KR Class

Developed Membrane-type Liquefied Hydrogen Cargo and Received Approval in Principle from LR Class

Received Approval in Principle for design of 'VLCC for Ammonia fuel Ready' from DNV Class

Received Approval in Principle for design of 'fuel cell propulsion LNG carrier' from DNV Class

Received Approval in Principle For '40K LCO2 carrier'

Received Approval in Principle For 'methanol propulsion 16K container ships'

Received Approval in Principle For 'ammonia-fueled supply system (container ships, tanker ships)'

Received Approval for '200K VLAC (Very Large Ammonia Carrier)'

Received Approval in Principle For 'developed FCSU (Floating CO2 Storage Unit)'

Cooperation for 'ammonia-dual fueled propulsion aframax tankers and VLCC

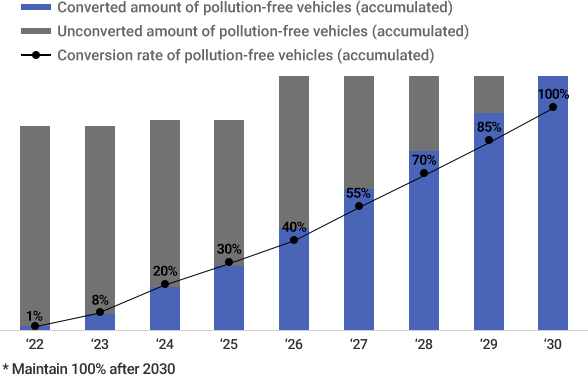

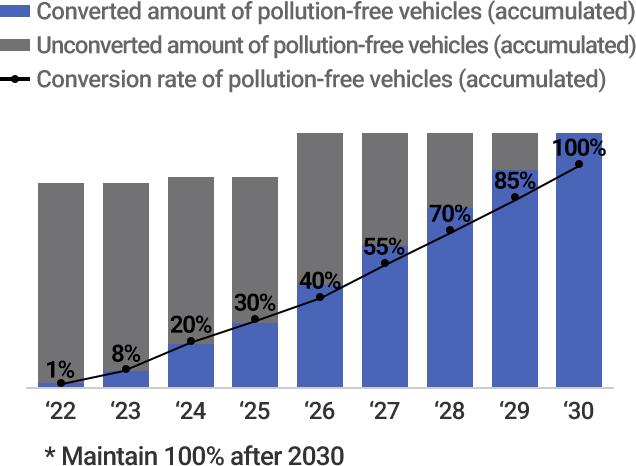

Samsung Heavy Industries joined the K-EV100 in February 2023, and is striving to convert 100% of its domestic business vehicles to pollution-free vehicles by 2030.

As of 2024, SHI converted total 20% of electric trucks and cars among domestic business vehicles.

Minimizing wastes and recycling resources is another effort to improve the global environment. Samsung Heavy Industries is striving to circulate resources by promoting waste reduction activities and increasing awareness of the use of disposable products by all employees.

Minimizing wastes landfill

Waste recycling rate

75% in 2028 → 90% in 2050

Reduction of disposable products use

Reducing copy papers

45% in 2030 → 90% in 2050

Through preemptive measure of pollutants such as air and water quality, we are striving to minimize pollutant emissions and to comply with laws and prevent environmental accidents.

Samsung Heavy Industries recognized the importance of restoring natural ecosystems and preserving biodiversity, and established policies. We will do our best to investigate the potential impact in the surrounding area and restore them.

| Type of indicator | indicator | How to collect data | How to respond |

|---|---|---|---|

| Water quality and pollution control |

|

Sample measurement | Enhancement of eco friendly facilities/activities in the workplace |

| Biological species protection and restoration |

|

|

|

| Monitoring the results |

|

|

|